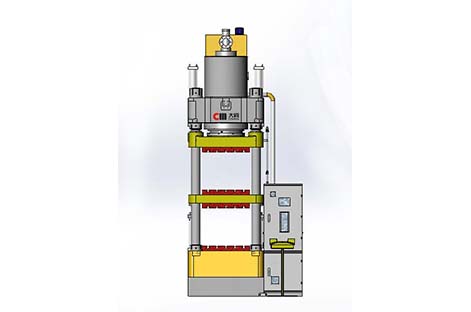

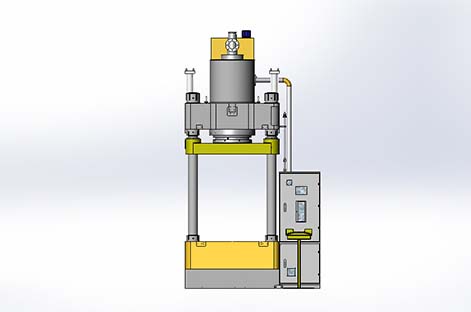

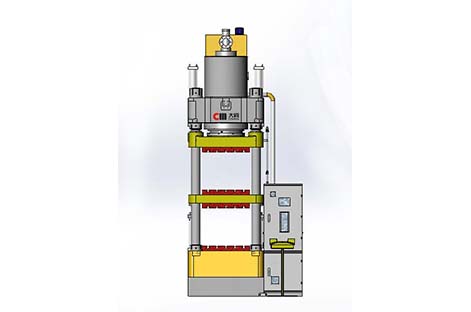

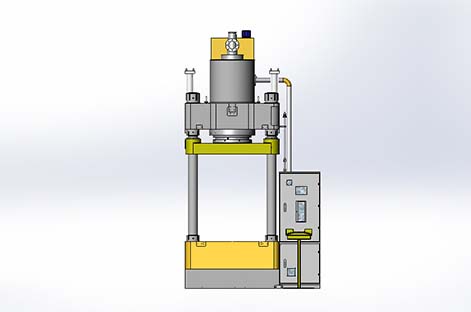

Drum type servo driven hydraulic press

CMSG Series Drum Type Single Layer / Multi Layers Servo Driven Hydraulic Press

Application

Brake pad, clutch plate, powder forming, etc.

Features

Machine structure: through finite element analysis, guarantee the strength and rigidity of hydraulic press;

Ease operation: user friendly HMI, ease for setting parameters and recipe storage;

Control system: PLC + HMI (Siemens brand), refer to pressing technology requirement set the parameters on HMI such as pressure, position, hold pressure, multi-pressing, etc;

Operation mode: equipped with independent hydraulic power pack and electrical system, central operation panel to perform four operation modes including inching, manual, semi-automatic and automatic;

Heating control: mold heating system is each cavity with independent control, the accuracy of temperature control in mold cavity within ±4°C, used of module mold designed, compact structure, pre-heat time less than 30 minutes, ease to change the mold;

Accuracy monitoring: used for linear scale and pressure sensor to monitor the position and pressure, enhance the pressing accuracy;

Pressing accuracy: repeatability of ram pressure achieve to ±3%, control the scrap rate of products caused by machine accuracy;

Energy saving: used of servo motor driving system can achieve energy saving 30 – 50%;

Low noise level: used of servo motor driving system, fulfill different speed and pressure of pressing requirement, ensures the stability of movement, lower noise level;

Selectivity: Number of layer as customer requirement;

Option: mold transfer mechanism, mold hold mechanism, vacuum system, etc;

Automatic production: different type of auxiliary production device can be designed as customer requested;

(Induction motor driving system as option)

WeChat QR code

WeChat QR code Tiktok QR code

Tiktok QR code